Inventory Intelligence

One of the most powerful inventory engines on the marketInventory Intelligence

Benefit from one of the most powerful Inventory engines on the market within SYM-PAC’s Retail Management Solution.

SYM-PAC’s huge range of standard Inventory functions, plus retail intelligence tools building on your own store data, gives you a powerful edge for your merchandising.

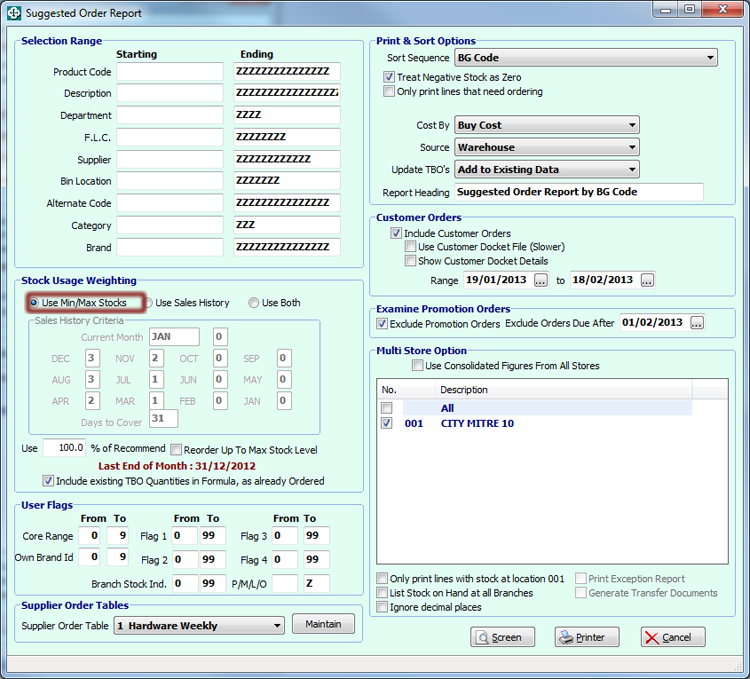

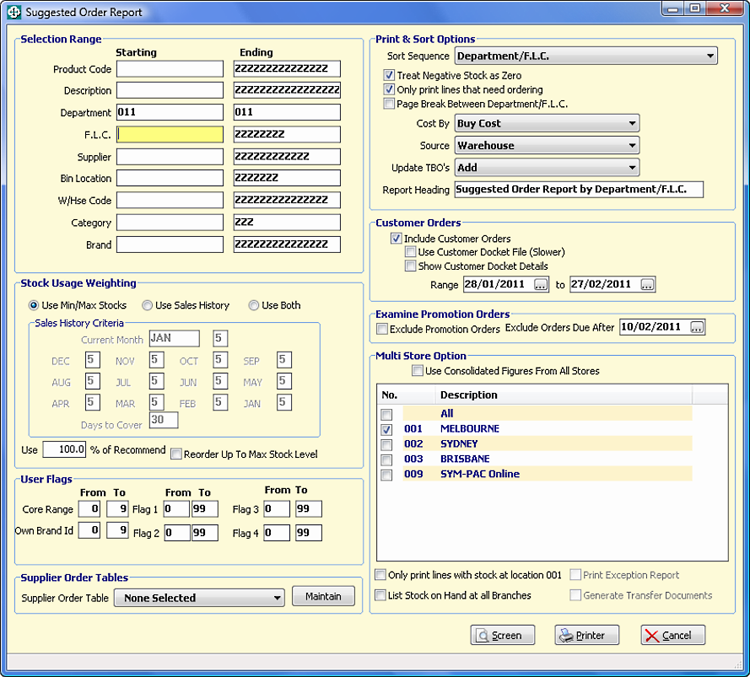

Suggested Ordering

- Suggest an order for Warehouse, Agency & Direct, Suppliers.

- Add items into the TBO (To Be Ordered) system for editing and purchase order creation.

- Sort and view suppliers to establish if suppliers minimum order values have been met.

- Saves staff time spent on scanning products into PDAs and PDEs and possible overstocking.

- Eliminates the need to create manual purchase orders for stock.

- Uses Stock On Hand and Stock On Order to establish if an order is required.

- Suggested Order quantities are based on rate of sale.

- Suggested orders can be given to reps to review and check stock on hand.

- Ability to set up order tables for suppliers, seasonal products (for example — watering), and for groups of products (for example — paint).

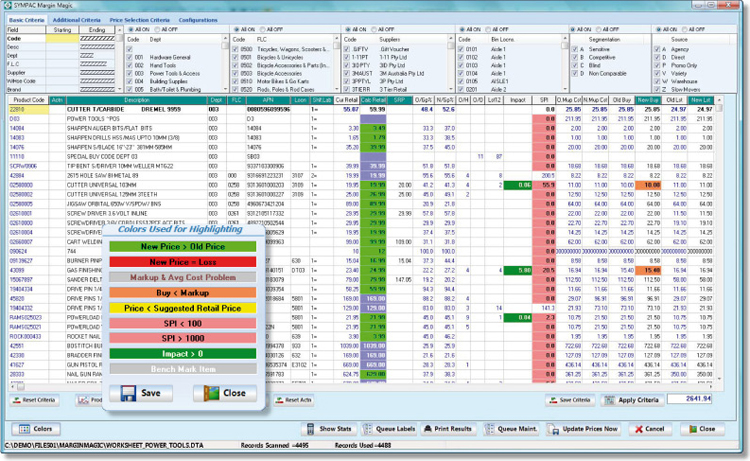

SPI Reporting

SPI = Stock Productivity Index, which is a measure of how efficiently the stock is performing.

- Quickly identifies products that are performing poorly — for fast & accurate decisions with merchandising strategy.

- Can be run as a summary and then drill down to specific products by various sorts, for example — by bin location.

- Identifies products where stock on hand is too high for the rate of sale.

- Identifies products which have a low gross profit.

- Identifies products with low stock turns — and also those fast selling products with high stock turns.

- Gives you the information you need — instantly — to make your stock more productive.

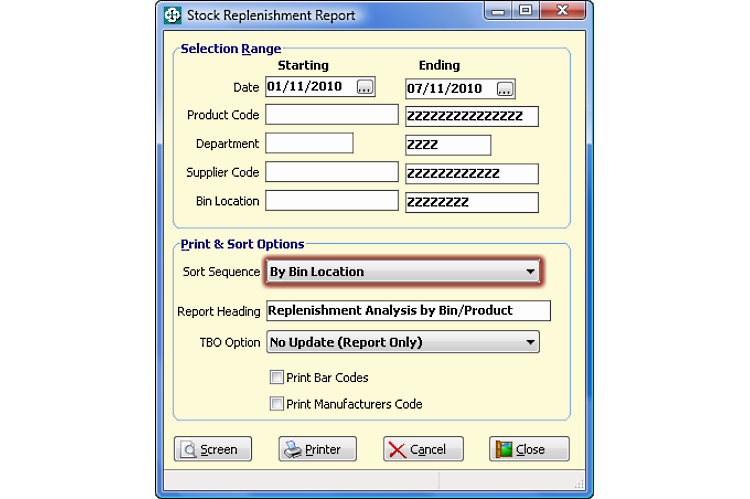

Stock Replenishment

- Replaces stock sold for a given date range

- Adds products that need to ordered into the TBO system

- Used for new stores who may not have sales history or Min Max quantities set

- Saves ordering time as order is suggested and added to the TBO system

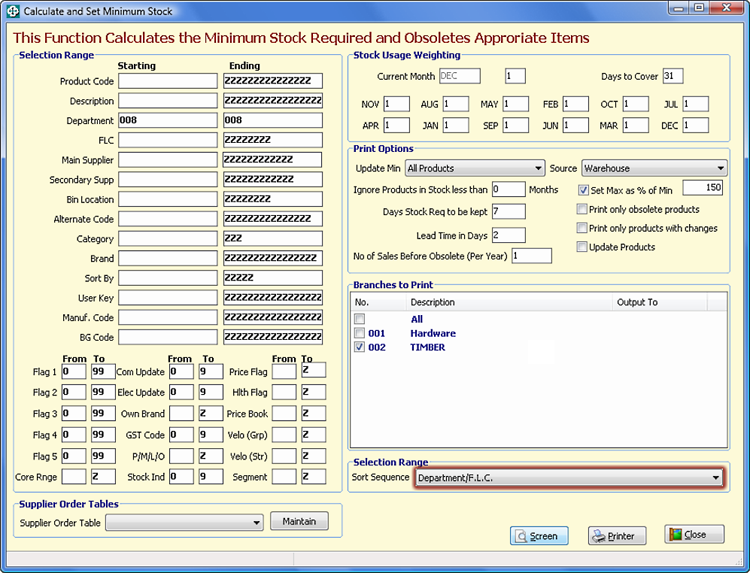

Automated Min/Maxes with Overstock Reporting

- Set Min Max for a range or ranges of criteria.

- Set Min Max for a range of suppliers through tables.

- Fully functional for days stock required and lead times.

- Reduces time manually setting Min Max by each product, supplier or department.

- Reports where there are over stocks.

- Takes into account re-order quantities.

- Obsoletes slow selling products.

- Can be run in report mode so you can view what will change.

- Combined with Suggested Ordering, this process will reduce slow selling inventory and increase better selling inventory.

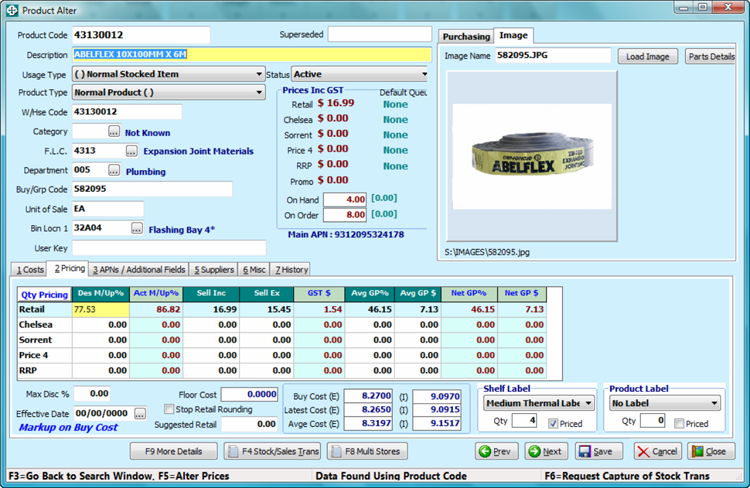

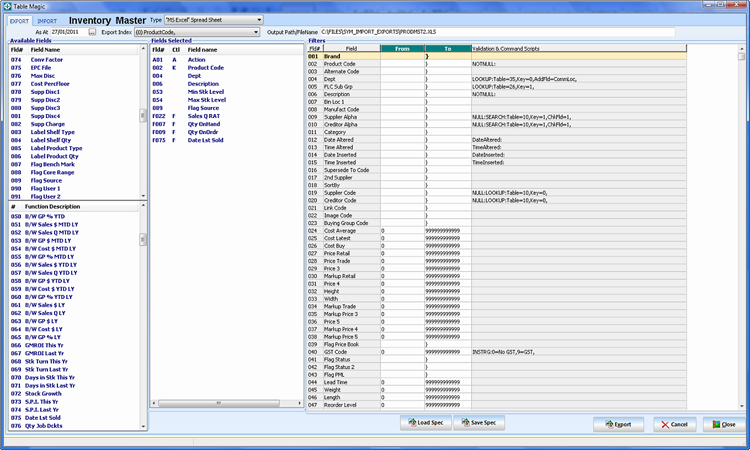

Import & Export Min/Maxes

- Export data with your selection criteria.

- Sort data using Excel sort tools.

- Enter in the Min Max levels.

- Import back into SYM-PAC and changes are effected immediately.

- Quick and efficient way to manipulate data.

- Time saving on keying in products individually.

Inventory

Keep up to date ::

Signup to the

SYM-talk newsletter today.

SYM-talk newsletter today.